Design Resource

Traditional Silver Jewelry - Kutch, Gujarat

Silver Jewelry

by

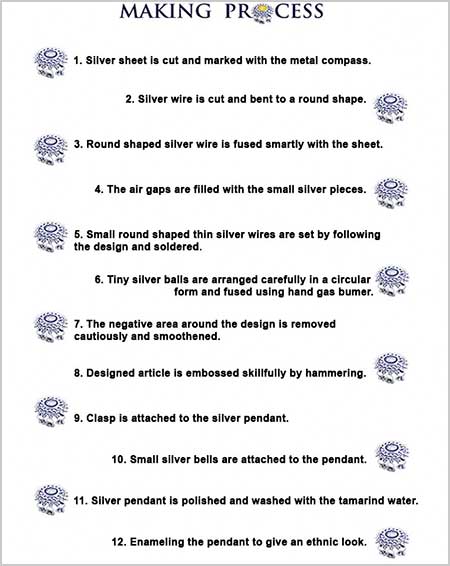

Silver is the basic material for traditional silver jewelry making. Initially, the silver sheet is cut with the help of a metal sheet cutter according to the required size and design. Then the silver sheet is slightly heated to make it soft using a hand gas burner and marked with the metal compass. The silver wire is cut and bent to a round shape. Then the shaped silver wire is placed on the silver sheet by dipping the wire in solution (water-soluble flux paste and water) and heated so that the wire fused smartly with the sheet. Artisan checks whether there is an air gap or not. If there is any gap, the small silver pieces, which are dipped in flux solution, are placed in-between to fill the gap. Then small round shaped thin metal wires is arranged by following the actual design and again soldered.

The thin silver wire is cut into small pieces and dipped in a solution made of water and water-soluble flux paste. Then the small pieces are arranged in a row and fired with the hand gas burner so that the small silver sticks are converted into tiny silver balls. These tiny silver balls are immersed in the solution and then arranged carefully in a circular form by glancing at the real design. Then the article is again fired and cooled by sinking in normal water. The negative area around the design is removed cautiously with the help of a metal sheet cutter. After removing the unwanted metal, the sharp edges are smoothened by using filer. The designed article is embossed by hammering the customized impression tool on the article. Once finished with the embossing, flat round shaped silver wire is added at the center and fused with the article.

Artisan works with the detailing part and the clasp for the traditional silver pendant is attached by soldering. Whereas in the other hand small bells are made manually by heating the tiny silver pieces, which turn into a sphere shape and the hook, is attached to get a bell form and soldered to the silver pendant. Then the article is polished and washed with tamarind water. Enamelling is done neatly to give an ethnic look.